Frequently asked questions and answers

What should a press inquiry look like?

A valid inquiry for the printing of books, boxes, brochures or other printed materials should contain the following information:

• Name of the client

• Product name

• Circulation

• Format (product dimensions)

• Scope (number of pages or sheets)

• Type and weight of paper

• Printing (printing mode – number of colors)

• Finishing (types of finishing of which the product consists)

• Packaging method (in packages or boxes)

What is the difference between digital and offset printing?

Apart from technological differences, the essential difference is the different purpose of these two techniques. Digital printing is intended for the production of smaller (up to 200 pcs) and personalized editions, while offset printing is intended for the production of larger editions. Today, digital printing is of the same quality as offset printing, so there are no major differences.

Which department should I call when I want to ask a question?

As a rule, all communication should take place through the Sales Department, although some technical matters are also handled with the Technology and Prepress departments.

Which printing paper is best to use?

There are different types of paper with different properties and at the same time with their advantages and disadvantages. There are, for example, woodless, double-sided coated papers that come in a matte or glossy version, larger or smaller volume, then woodless offset papers – voluminous, smooth, rough or 100% recycled. Coated papers, matte or glossy, are generally considered to be best for high-quality color reproduction in print, while offset papers are used to print memos, envelopes or, say, a book block, or materials that contain predominantly text.

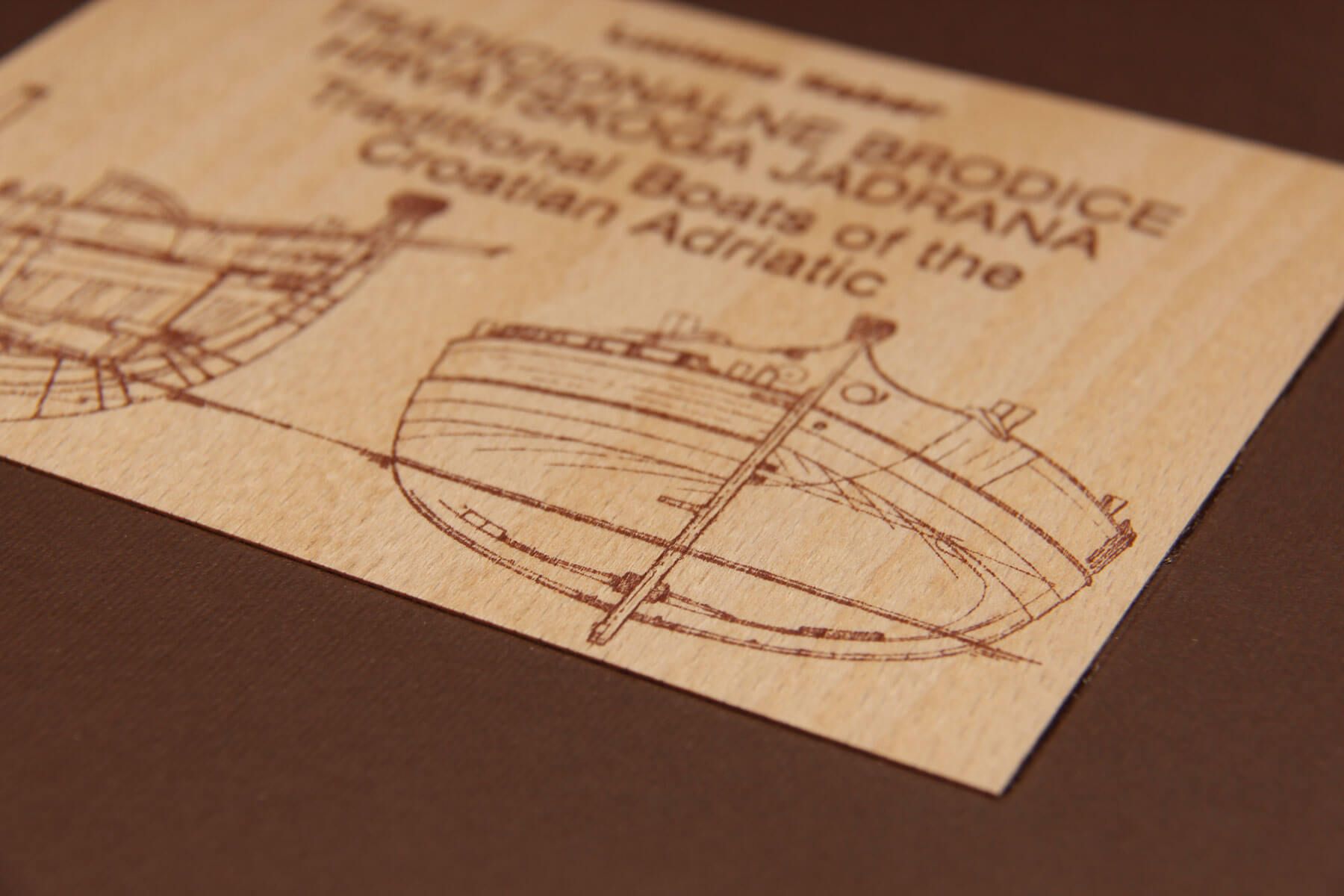

Coated cartons are used to make packaging boxes, as well as the very popular Kraft packaging natur cartons. Boxes can also be made of other materials.

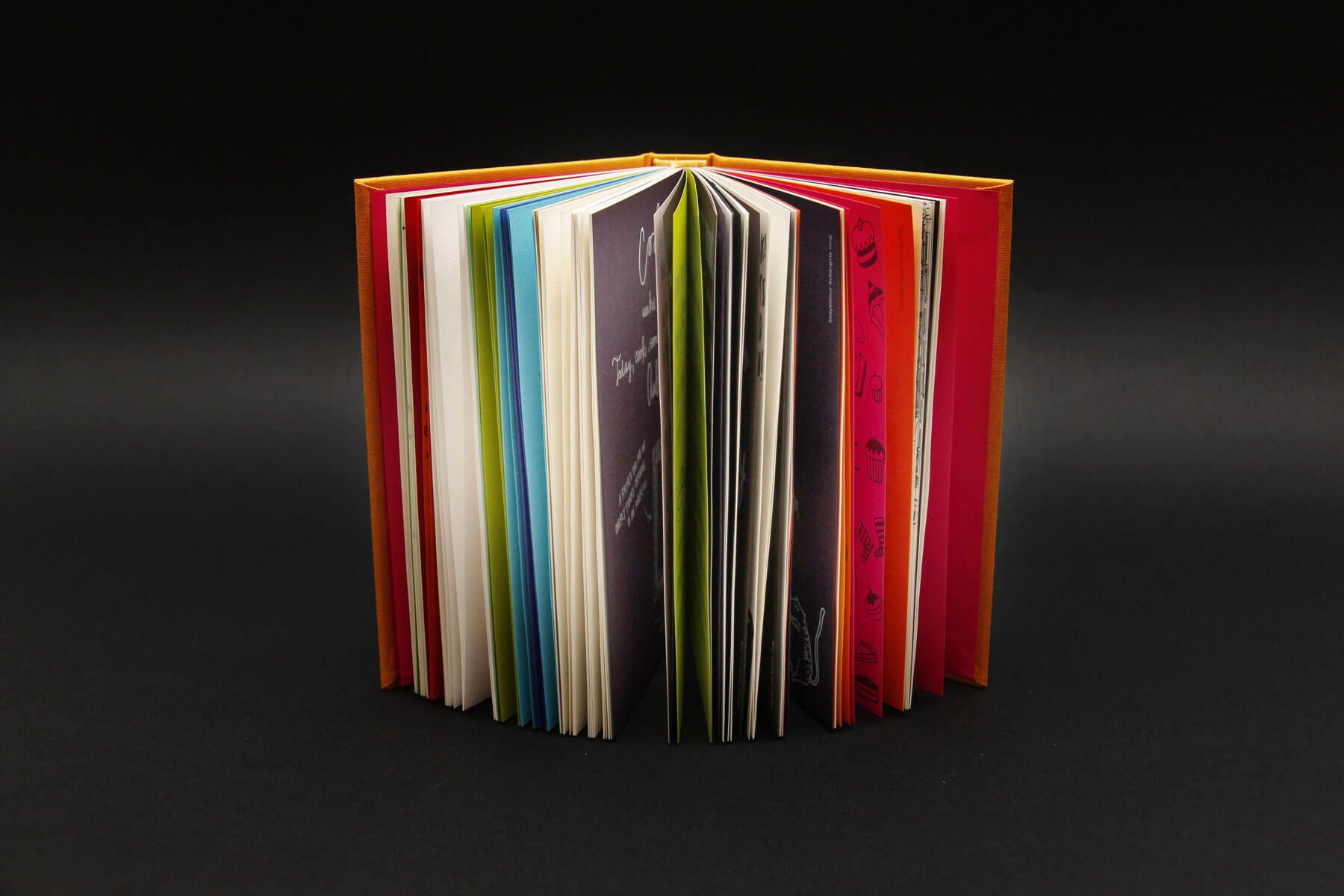

If you are working on an art catalog, sophisticated corporate material or developing more expensive packaging, then we recommend printing on textured and voluminous papers of high quality and fineness of material.

Can you make me a punch tool?

In our Punch Development Department, we can make the punch tool you need for your product, and at the same time a model of that product so that you can check the dimensions and quality of the printed product before making it.

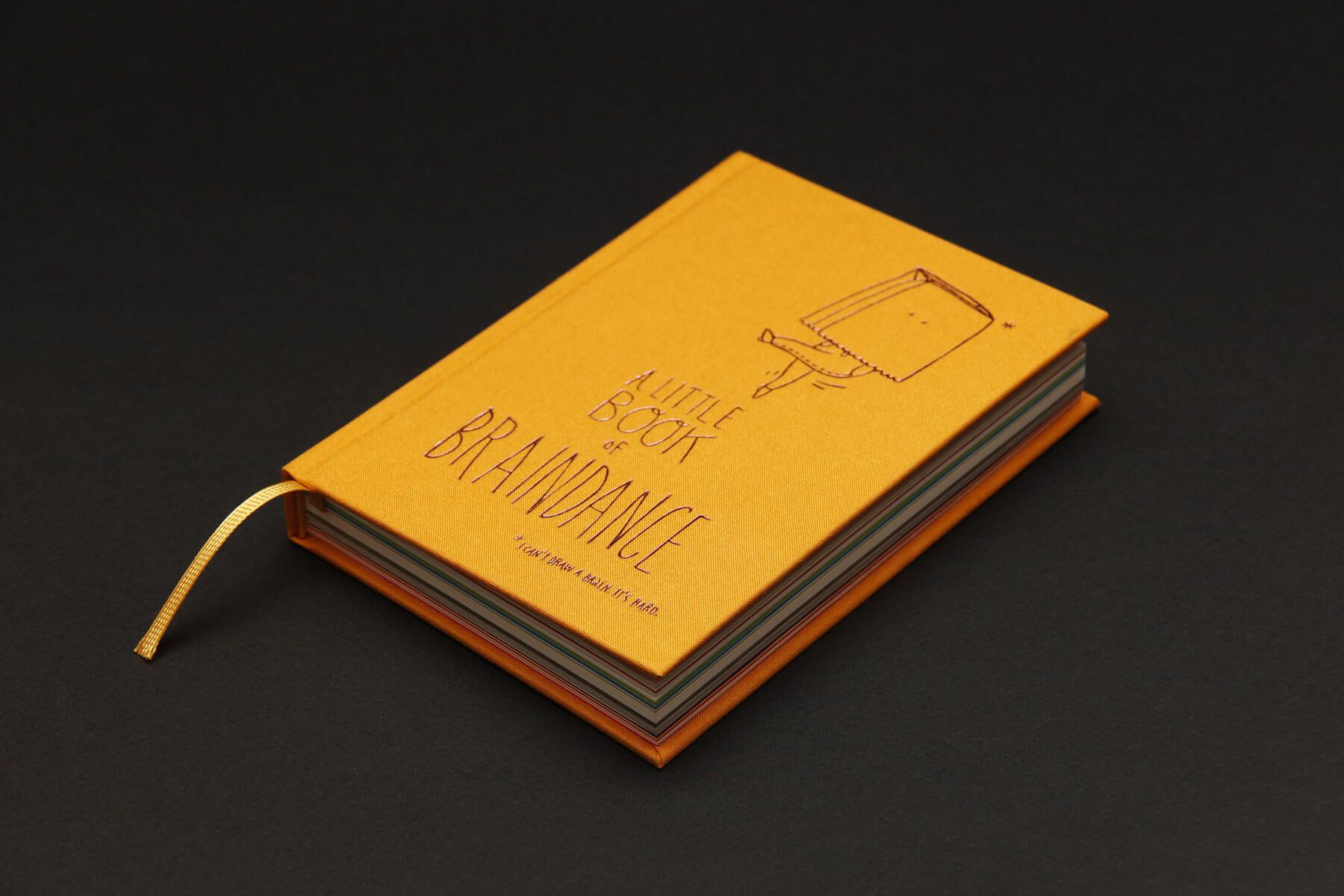

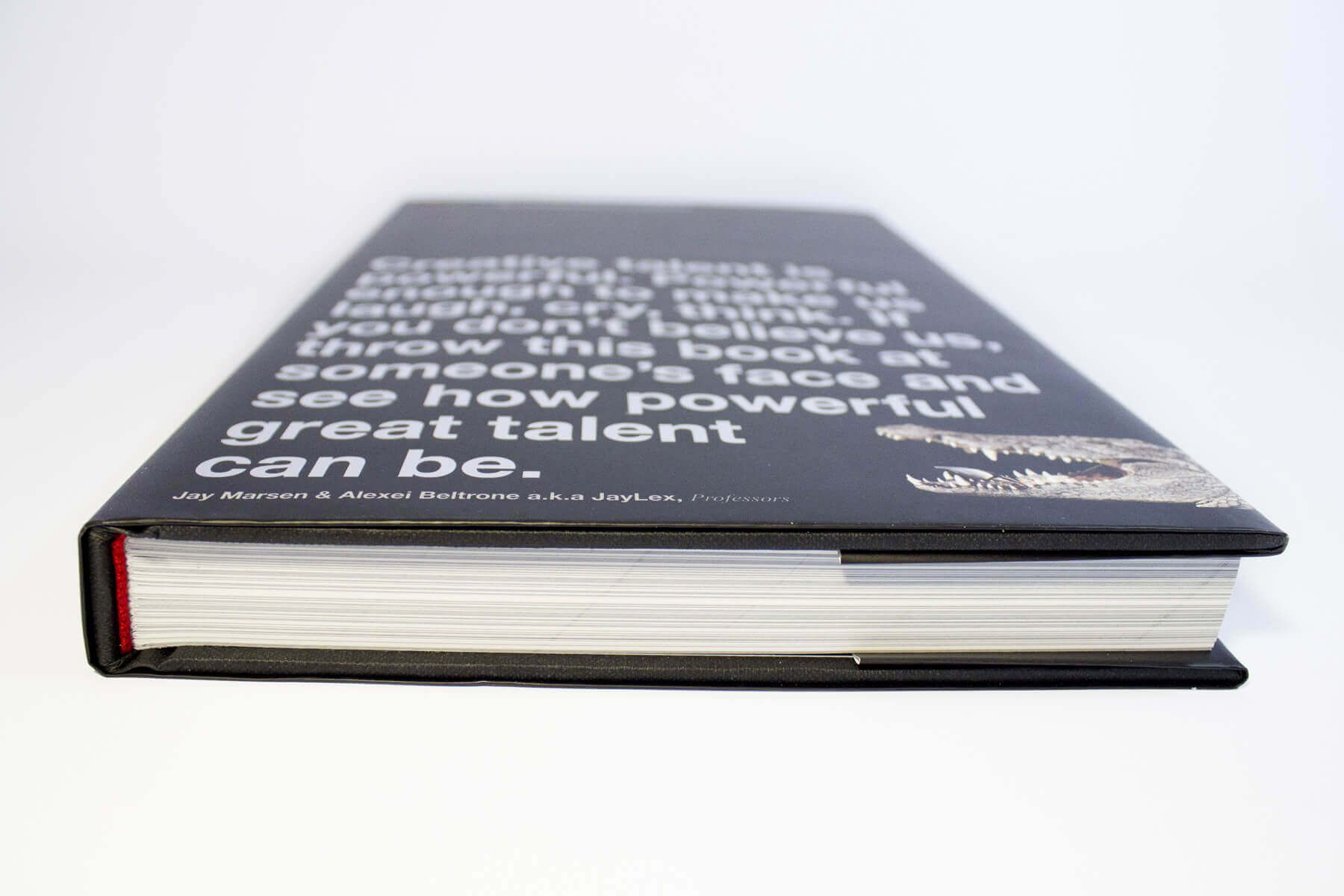

In which case hard binding is recommended and in which soft binding?

The type of binding depends on the customer’s wishes, but it is common for more luxurious editions to be imported in hardcover, but it is not a strict rule.

Does the number of pages or the scope of material condition the choice of binding?

When choosing a binding, which largely depends on the thickness of the paper on which it is printed, we are guided by the principle that for a smaller number of pages we take in principle stapled binding (eg up to 64 pages for 135g/m2 paper), and for a larger number of pages glued binding. Glued binding can be done for a smaller number of pages, but it is not recommended if the spine is less than 4 mm thick. In any case, you can always contact our sales representatives or technologists for advice on the type of binding.