From work order to printed product

We are different from other printing houses. That is unquestionable. Our clients know they will get what they want. From the moment we receive the order, our mission is a top final product and a satisfied customer. The state-of-the-art technological equipment of the printing house and the quality organization ensure us an advantage over the competition.

On these pages you can get acquainted with the production processes in Kerschoffset, and you will also get a basic overview of the most modern processes of creating printed products, even if you are not a graphic expert.

First phase: to the work order

Calculation > Estimation > Resource Management > Work Order > Head of Department (facility)

Calculation

In the first phase of the creation of the printed product, the estimator processes the customers request. From this complex process we learn the cost of production, the required quantities of raw materials and the time required for realization.

Resource management

We use the information obtained from the calculation to manage resources. Then we find out how much paper is in stock, how much more needs to be ordered, when and what production resources are free (machines and people) and what the final price of the product will be. Only after such data processing can a production work order be opened.

Work order

According to the data from the work order, the managers of individual production phases manage the process, with a special focus on the continuity of all phases.

Second phase: production

Production is traditionally divided into three basic units: prepress, printing and finishing.

Prepress > Printing plate > Printing > Printed sheets > Finishing, storage > Product

Prepress

It implies a part of the production process up to the printing plates – an aluminum medium, coated with a photosensitive and color-sensitive substance, which is placed on the cylinders of the printing machine.

CTP (Computer to Plate) devices for direct “printing”, ie illumination of printing plates, have been a standard in our production process for many years. With their introduction, we have significantly reduced the time and cost of production, and also significantly improving the quality of the print (due to the direct transfer of content to the printing plates).

Printing

The printing process on modern machines, such as the ones used in Kerschoffset, reaches speeds of up to 18,000 prints per hour in 1-5 colors at a time, on one side or on both sides of the sheet up to size B1 – depending on the requirement. It is very important to maintain precisely defined conditions in which such an advanced printing process takes place. In order to achieve a quality print in accordance with the requirements of the profession and the market, we use electronically precise methods in determining and measuring the adequate application of paint and their mutual, micrometer-accurate alignment.

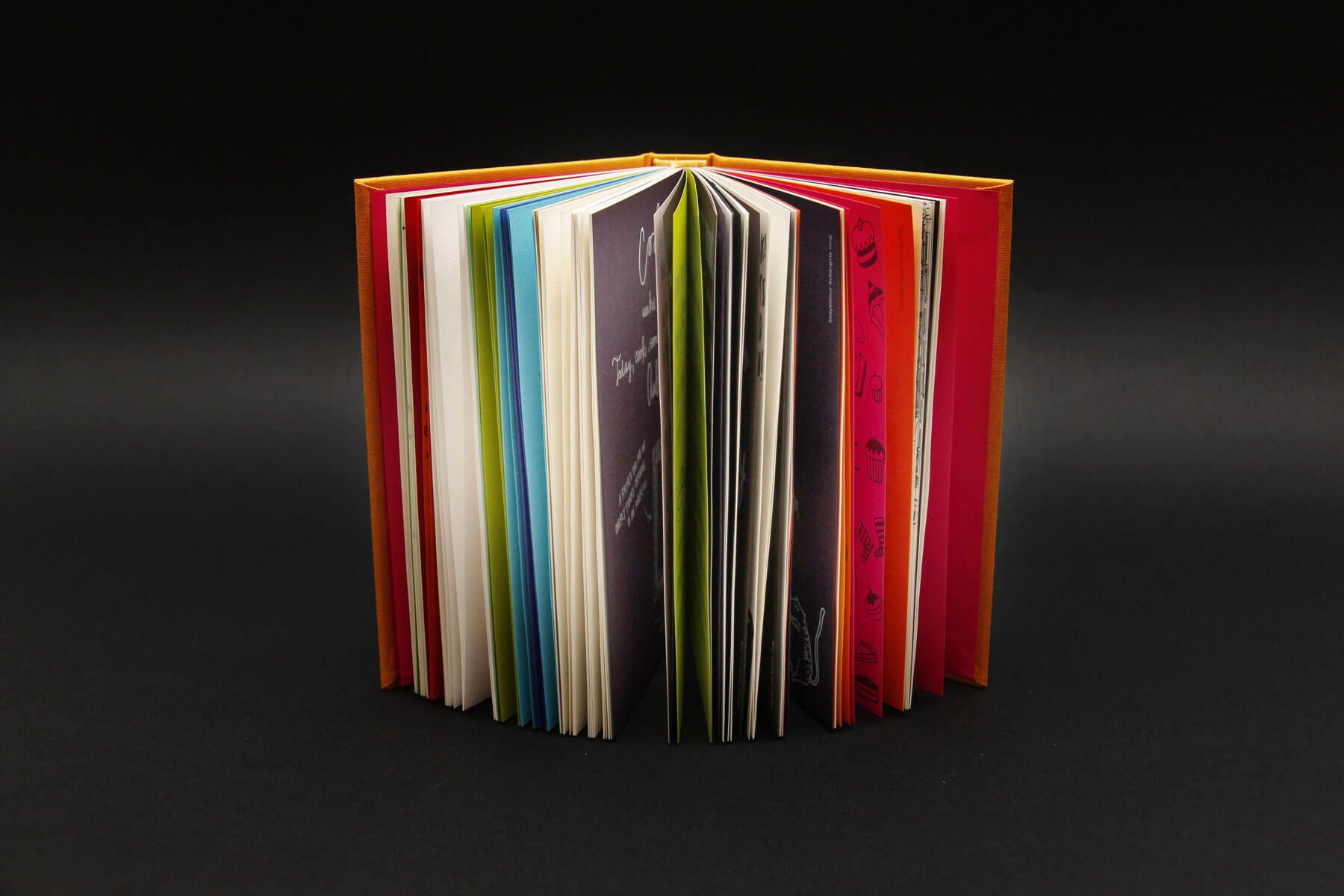

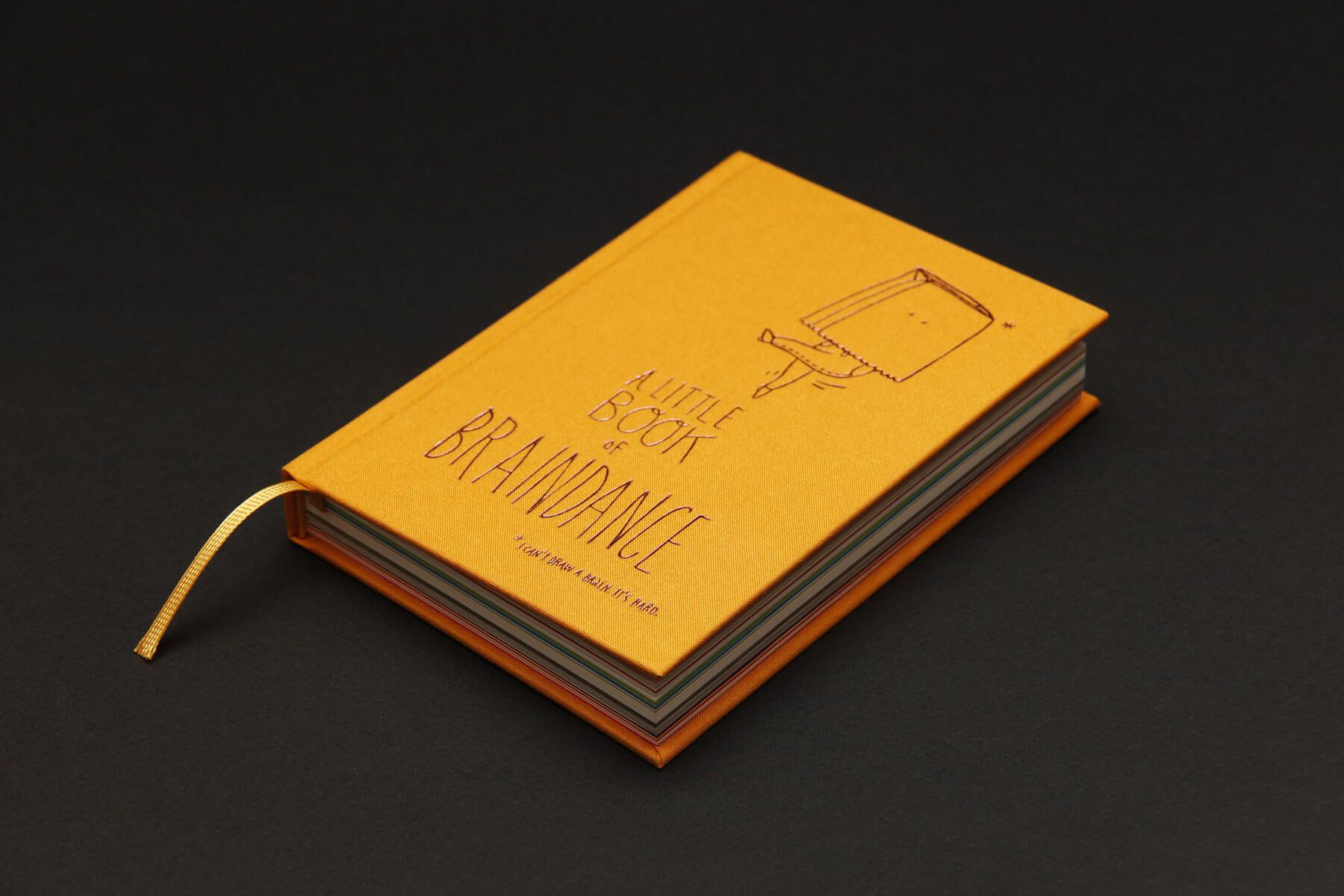

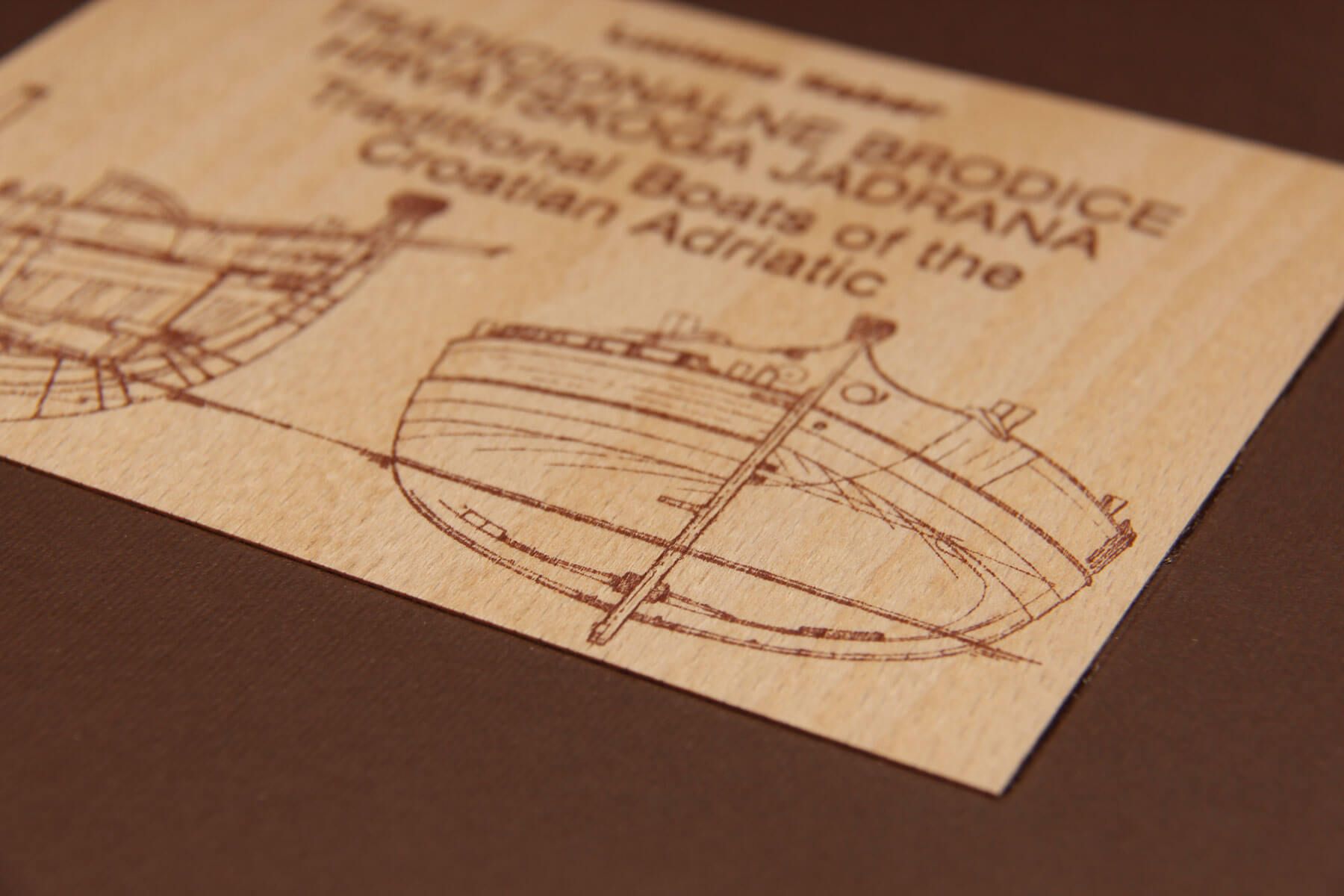

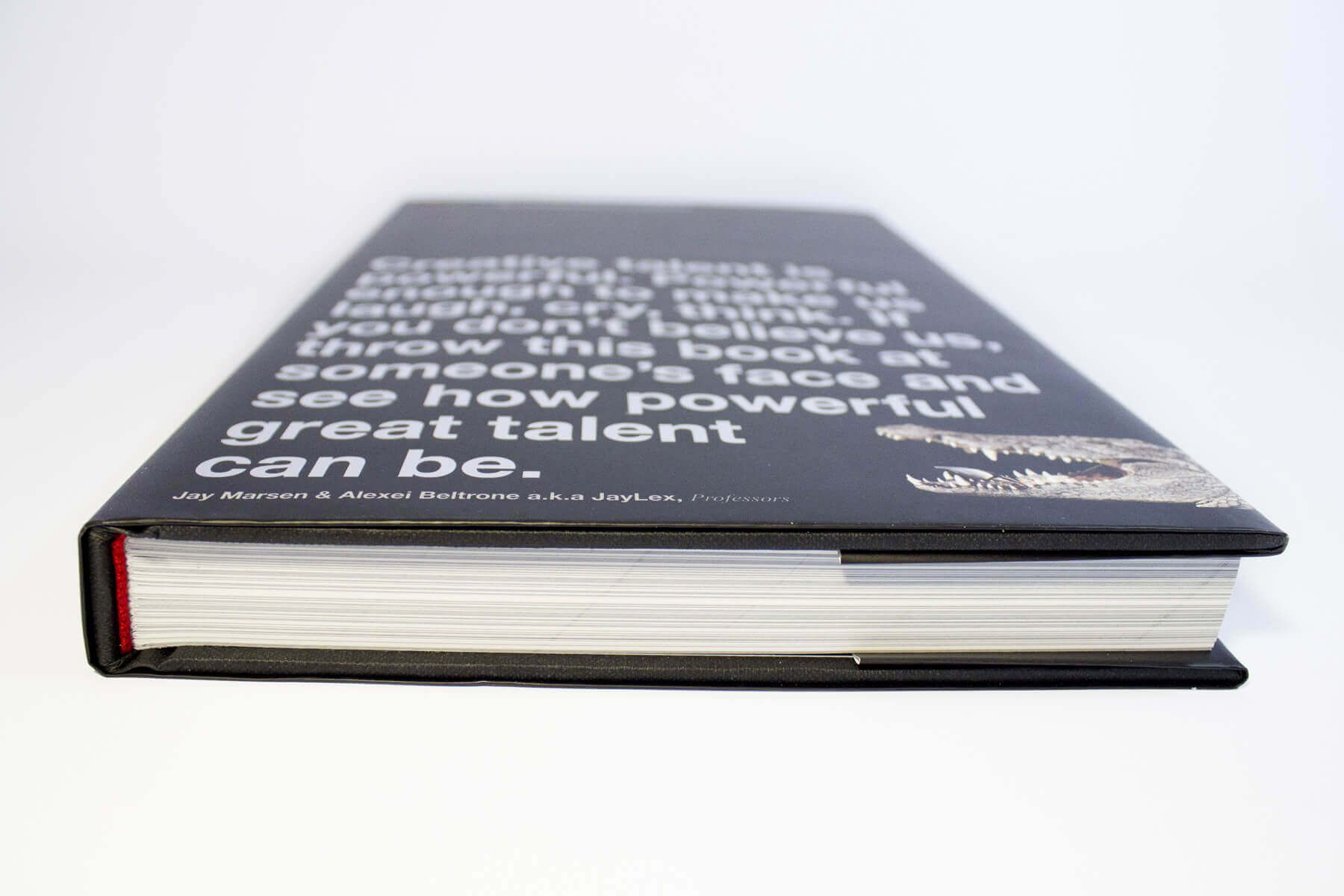

Finishing

After the paint has dried, depending on the type of paint, paper and method of application, the printed sheets are mechanically and thermally processed to the required dimensions and shapes. The number of combinations in finishing is almost an infinite one, so it is impossible to list them all, we can only say that we are able to perform those simple as well as the most creative and complicated finishing.

Third phase: distribution

At this stage, after careful quality control, the product is packed in packages and distributed by our delivery vehicles or some other agreed method, depending on the customer’s wishes.